Difference between revisions of "Flow Network"

| (7 intermediate revisions by one other user not shown) | |||

| Line 7: | Line 7: | ||

| − | ==Universal | + | ==Universal Connectivity== |

All Flow-enabled inventories follow a universal symbol convention to demarcate inlets and outlets. | All Flow-enabled inventories follow a universal symbol convention to demarcate inlets and outlets. | ||

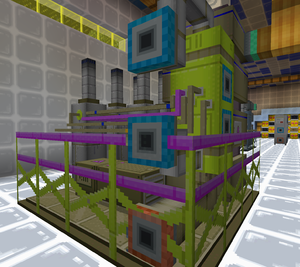

*Blue squares indicate inputs and are mapped to specific input slots on the inventory GUI.<br>[[File:Inlets_on_bioreactor.png|frameless|Blue and Red inlets shown on a [[BioReactor|Bio Reactor]]]]<br> | *Blue squares indicate inputs and are mapped to specific input slots on the inventory GUI.<br>[[File:Inlets_on_bioreactor.png|frameless|Blue and Red inlets shown on a [[BioReactor|Bio Reactor]]]]<br> | ||

| Line 14: | Line 14: | ||

==Building Networks== | ==Building Networks== | ||

| − | |||

Networks should be built in the following order: | Networks should be built in the following order: | ||

# Placement of Inventories in the world at their desired locations, preferably with easy access to their demarcated connector points | # Placement of Inventories in the world at their desired locations, preferably with easy access to their demarcated connector points | ||

# Placement of [[Pump|Pumps]] that push or pull items into and out of inventories. There must be one pump per pipe section that transfers items between inventories. | # Placement of [[Pump|Pumps]] that push or pull items into and out of inventories. There must be one pump per pipe section that transfers items between inventories. | ||

# Placement of [[Pipe|pipes]] '''from the destination''' ''to the origination'' to ensure items move in the right direction. Pipes are directional and will prevent flow networks from working if placed inversely. | # Placement of [[Pipe|pipes]] '''from the destination''' ''to the origination'' to ensure items move in the right direction. Pipes are directional and will prevent flow networks from working if placed inversely. | ||

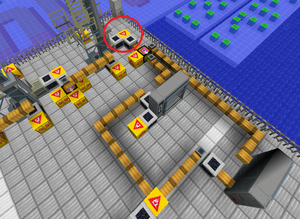

| + | As shown in the red circle in the image below, one pump pulls the outputs of the [[Distillation Column|distillation column]] to a chest and another pushes the items from the [[Plastic Chest|plastic chest]] to a [[Flow Regulator|flow regulator]]. Only one pump is necessary to push items through multiple outlets in a Flow Regulator<br> | ||

| + | [[File:Pumps_on_flownetwork.png|frameless|Example flow network has at one pump per pipe section. As shown, only one pump is needed to enable flow through all outputs of a flow regulator]] | ||

| + | <br> | ||

==Working with Chests== | ==Working with Chests== | ||

| − | Like Hoppers, [[Tree | + | [[Plastic Chest|Plastic chests]] can be used to [[Upcycling|upcycle]] items from smaller containers to bigger containers. Strategically placing plastic chests in your flow network enables automatic usage of higher-efficiency recipes that provide increased yields at scale. Wooden chests will not change the container-size of polycraft items, enabling stacks of 64 bags to be fed into injection molders and other inventories that process specific [[Upcycling|container sizes]] of polymers. [[Unpacker|Unpackers]] can be used to [[Downcycling|down-cycle]] items and should also be strategically deployed, as shown below. |

| + | |||

| + | Like Hoppers, [[Tree Tap|tree taps]] and [[Unpacker|unpackers]] can be used to push/pull items out of Chests and [[Plastic Chest|plastic chests]] without needing a [[Pump|pump]]. As shown in the image below, an [[Unpacker|unpacker]] feeds down-cycles powder kegs of polymers from a Plastic Chest to bags of polymers suitable for use in an Injection Molder. As shown, gravity is an important aspect when utilizing these inventories.<br> | ||

| + | [[File:Unpacker_stack.png|frameless|blah-blah]] | ||

| + | <br>Above, the [[Pipe|pipe]] on the left provides an input to the top, purple [[Unpacker]], which then feeds its outputs to the chest below. A [[Pump|pump]] can be used to divert parts of the ''input'' (not output) from the Unpacker to another unpacker, enabling parallel unpacking. In this example, Drums of polymer are unpacked to sacks and then bags, which are then fed to the [[Injection Molder|Injection molder]] at the bottom. | ||

==Properties== | ==Properties== | ||

Latest revision as of 04:58, 9 November 2020

Description

A flow network is a system composed of pipes that connect multiple inventories such as plastic chests, pumps, flow regulators, distillation columns, steam crackers, merox treatment units, chemical processors and others. A flow network is defined by a pump. Each pumped connection is its own flow network. Right-Clicking (activating) the pump allows the insertion of fuel and indicates the status of the flow network. Red text means that the flow network is not valid. Green text means that it is valid.

A flow network is valid when it connects a source to an default target output. If flow regulators are added into a flow network, the items that are placed in the various slots are selectively piped in that direction. Thus a single flow network could have many, many branches as dictated by the flow regulators.

Whenever a flow network runs into a target inventory, a new flow network can be created that pumps items out of that same inventory. For instance, you could distill things multiple times in an automated fashion using several flow networks. Each flow network must have a default target.

Universal Connectivity

All Flow-enabled inventories follow a universal symbol convention to demarcate inlets and outlets.

- Blue squares indicate inputs and are mapped to specific input slots on the inventory GUI.

- Red squares indicate inputs for the fuel slot on fueled inventories (pumps, lamps, and other small inventories do not have this available)

- Green squares indicate outputs for the resultant products to be piped out of the inventory

Building Networks

Networks should be built in the following order:

- Placement of Inventories in the world at their desired locations, preferably with easy access to their demarcated connector points

- Placement of Pumps that push or pull items into and out of inventories. There must be one pump per pipe section that transfers items between inventories.

- Placement of pipes from the destination to the origination to ensure items move in the right direction. Pipes are directional and will prevent flow networks from working if placed inversely.

As shown in the red circle in the image below, one pump pulls the outputs of the distillation column to a chest and another pushes the items from the plastic chest to a flow regulator. Only one pump is necessary to push items through multiple outlets in a Flow Regulator

Working with Chests

Plastic chests can be used to upcycle items from smaller containers to bigger containers. Strategically placing plastic chests in your flow network enables automatic usage of higher-efficiency recipes that provide increased yields at scale. Wooden chests will not change the container-size of polycraft items, enabling stacks of 64 bags to be fed into injection molders and other inventories that process specific container sizes of polymers. Unpackers can be used to down-cycle items and should also be strategically deployed, as shown below.

Like Hoppers, tree taps and unpackers can be used to push/pull items out of Chests and plastic chests without needing a pump. As shown in the image below, an unpacker feeds down-cycles powder kegs of polymers from a Plastic Chest to bags of polymers suitable for use in an Injection Molder. As shown, gravity is an important aspect when utilizing these inventories.

Above, the pipe on the left provides an input to the top, purple Unpacker, which then feeds its outputs to the chest below. A pump can be used to divert parts of the input (not output) from the Unpacker to another unpacker, enabling parallel unpacking. In this example, Drums of polymer are unpacked to sacks and then bags, which are then fed to the Injection molder at the bottom.

Properties

| Name | Value |

|---|---|

| Release Version | 1.0.7 |